Ergonomic principles are the cornerstone of creating safer and more efficient workplaces, directly impacting employee health and productivity. According to the U.S. Bureau of Labor Statistics, musculoskeletal disorders (MSDs) accounted for nearly 30% of all workplace injuries in 2022, leading to over 320,000 reported cases and costing businesses billions annually (BLS, 2023). The science of ergonomics, which dates back to the early 20th century during the industrial revolution, emerged to address the growing need for designing jobs that fit human capabilities and limitations rather than forcing workers to adapt to poorly designed tasks and tools.

Implementing valid ergonomic principles helps reduce muscle fatigue, prevent common injuries like carpal tunnel syndrome and lower back pain, and enhance overall workplace efficiency. By aligning the workspace with human anatomy, strength, and sensory abilities, these principles form the foundation for sustainable occupational health and safety programs. Understanding and applying ergonomic principles is not just a regulatory requirement but a strategic investment in workforce wellbeing and business success.

Ergonomics can be seen in three different categories

Physical ergonomics: This is concerned with human anatomy, and some of the anthropometric, physiological, and biomechanical characteristics as they relate to physical activity. It involves designing user interaction with equipment and workplaces to fit the user.

Cognitive ergonomics: This is concerned with mental processes, such as perception, memory, reasoning, and motor response, as they affect interactions among humans and other elements of a system.

Organizational ergonomics: Organizational ergonomics is concerned with the optimization of socio-technical systems, including their organizational structures, policies, and processes.

In this article, we will be concentrating mainly on physical ergonomics.

Importance of ergonomics in the workplace

Ergonomics—the science of designing work environments to fit the needs of workers—plays a critical role in modern workplaces. Implementing effective ergonomic practices benefits both employees and employers in many ways. Here are seven key reasons why ergonomics is important in the workplace:

1. Reduces Risk of Musculoskeletal Disorders (MSDs): One of the most important benefits of ergonomics is the prevention of MSDs, such as carpal tunnel syndrome, tendonitis, and back pain. By designing tasks and workstations to fit the worker’s body, ergonomics helps minimize repetitive strain and awkward postures that lead to injury.

2. Improves Employee Comfort and Well-being: Ergonomic workplaces reduce physical stress and fatigue, leading to greater comfort. When employees feel physically comfortable, their overall well-being improves, which positively affects mental health and job satisfaction.

3. Enhances Productivity and Efficiency: Workers who are comfortable and free from pain can perform tasks faster and with greater accuracy. Ergonomic designs reduce unnecessary motions and make tools and equipment easier to use, directly boosting productivity.

4. Decreases Absenteeism and Turnover: Work-related injuries often lead to time off and even long-term disability. Ergonomics lowers injury rates, which means fewer sick days and less turnover. This stability saves employers costs associated with recruitment and training.

5. Lower Workers’ Compensation and Medical Costs: Preventing ergonomic injuries helps reduce the number and severity of compensation claims. Lower injury rates also mean fewer medical expenses related to workplace injuries, benefiting company finances.

6. Promotes a Positive Safety Culture: Prioritizing ergonomics signals that management cares about employee health. This fosters a culture of safety where workers feel valued, encouraging proactive reporting of hazards and engagement in safety programs.

7. Supports Legal and Regulatory Compliance: Many countries have regulations requiring employers to provide safe working conditions, including ergonomics. Compliance reduces legal risks and potential fines while demonstrating corporate responsibility.

Ergonomics Principles

Musculoskeletal Disorders (MSDs) are among the most common work-related injuries, costing businesses billions annually in lost productivity and compensation claims. Preventing MSDs begins with applying valid ergonomics principles tailored to the workplace. In this article, we explore 11 essential ergonomic principles to help you build a safer, healthier, and more productive environment for your workforce.

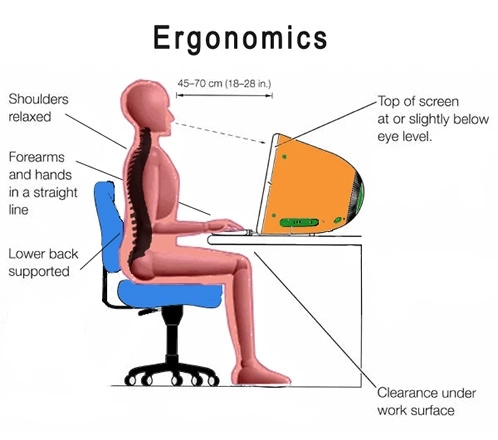

1. Maintain Neutral Posture

The neutral posture is a natural alignment of the body where joints are neither bent nor twisted. This reduces stress on muscles, tendons, and bones. When workers frequently operate outside this posture, such as slouching or reaching overhead, it leads to cumulative strain. To implement this, workstations should be designed to allow elbows to remain close to the body, wrists to stay straight, and the spine to be aligned. Adjustable chairs, sit-stand desks, and well-positioned monitors help reinforce neutral postures and minimize MSD risks. It’s also essential to train employees on recognizing and maintaining this posture during tasks.

2. Work in the Power Zone

The power zone refers to the area from mid-thigh to mid-chest, where the body can exert maximum strength with minimal effort. Working within this zone prevents excessive strain on muscles and reduces the risk of injuries from lifting, pushing, or pulling. For manual handling tasks, placing frequently used tools and materials within this area significantly improves efficiency and safety. This principle is especially effective in warehouses, manufacturing, and healthcare settings where lifting is frequent. Using carts, lifting aids, and proper shelving further supports this ergonomic principle.

3. Reduce Excessive Force

Applying excessive force—whether lifting, gripping, or pressing—can strain muscles and soft tissues, leading to fatigue and eventually MSDs. To counter this, tasks should be engineered to minimize required force. This can be achieved by using tools with ergonomic grips, maintaining equipment, reducing load weights, and introducing automation where possible. Additionally, educating workers about using body mechanics and pacing themselves during high-exertion tasks plays a vital role. Employers must monitor jobs involving repetitive high-force exertion to identify and redesign these tasks proactively.

4. Avoid Repetitive Motions

Performing the same motion repeatedly, especially under stress or awkward posture, can lead to cumulative trauma disorders. While repetition is unavoidable in many jobs, rotating tasks and providing micro-breaks can reduce strain. Implementing job rotation schedules allows different muscle groups to recover, minimizing the risk of overuse injuries. Additionally, automating highly repetitive tasks or redesigning them to require fewer movements can reduce the frequency of harmful motions. Training workers on proper techniques further protects against long-term MSD development.

5. Minimize Contact Stress

Contact stress occurs when a part of the body presses against a hard or sharp surface, impairing blood flow and nerve function. This can happen when wrists rest on hard desk edges or knees press into floor surfaces while kneeling. Over time, these stress points lead to discomfort and injury. Employers should introduce cushioning, rounded edges, anti-fatigue mats, and ergonomic padding where necessary. Equipment such as padded gloves or knee pads can also alleviate localized pressure. Regular assessments of contact stress points ensure interventions remain effective.

6. Maintain Comfortable Work Heights

Work surfaces should align with the nature of the task and the worker’s height to promote neutral posture. For precision work, slightly higher workstations reduce neck strain; for heavy lifting, lower heights closer to the power zone are ideal. Adjustable workbenches and chairs allow for customization based on individual needs. In shared workspaces, implementing height-adjustable tools and equipment supports a diverse workforce and reduces injury risk. Monitoring workstation setup during onboarding ensures workers begin with ergonomically optimized environments.

7. Promote Movement and Stretching

Static postures are just as harmful as repetitive movements. Encouraging periodic movement and stretching during shifts improves circulation, prevents stiffness, and reduces fatigue. Incorporating micro-breaks, standing meetings, and dynamic stretching routines into the daily workflow cultivates a movement-friendly culture. Desk-based workers should be prompted to stand or stretch every 30 minutes. These small but consistent actions prevent muscle imbalances and significantly lower the risk of developing MSDs over time.

8. Design for Variety and Flexibility

Monotony in tasks limits muscle usage diversity, increasing strain on specific body parts. Designing workstations and roles that allow for task variation not only prevents MSDs but also improves job satisfaction and productivity. Ergonomically, variation gives muscles a chance to rest and adapt. Examples include alternating between sitting and standing tasks or switching between manual and automated processes. In environments like assembly lines or offices, cross-training employees also offers operational flexibility while reducing ergonomic risk factors.

9. Provide Proper Lighting

Poor lighting contributes to awkward postures, especially when workers lean forward or twist to see better. This misalignment stresses the neck, shoulders, and spine. Adequate task lighting prevents eye strain and allows workers to maintain correct posture while focusing. Ergonomic lighting should eliminate glare, provide even illumination, and be adjustable to suit different tasks. Where screens are used, positioning them to reduce contrast and adjust brightness is equally important. Proper lighting indirectly but significantly influences ergonomic safety.

10. Use Ergonomically Designed Tools

Tools that do not fit the user’s hand or force the wrist into awkward positions increase the risk of MSDs. Ergonomically designed tools match the natural movement and grip strength of users, reducing strain. This includes features like padded handles, trigger mechanisms that require minimal force, and designs that keep the wrist in a neutral position. Investing in the right tools can dramatically improve worker comfort and task efficiency, especially in industries requiring repetitive tool use, such as construction, mechanics, and lab work.

11. Train and Involve Employees

Ergonomics isn’t a one-size-fits-all solution. Employees must be involved in identifying hazards and developing ergonomic improvements. Training helps workers recognize early symptoms of MSDs, adopt safe practices, and report issues promptly. Feedback from frontline workers ensures ergonomic interventions are practical and effective. Conducting regular toolbox talks, ergonomics assessments, and surveys builds a culture of safety and shared responsibility. When employees feel heard and trained, they become proactive contributors to workplace wellness.

Final Thoughts

Ergonomics is not just about comfort—it’s about preventing real injuries and creating sustainable work environments. By applying these 11 principles, organizations can significantly reduce the risk of musculoskeletal disorders, improve employee morale, and enhance productivity. The key lies in continual evaluation, employee involvement, and leadership commitment to safety excellence.

Want to improve your workplace ergonomics program? Start with a risk assessment and invite employee feedback. Prevention is more effective—and far less costly—than cure.

External Resource

Related Posts

Office Ergonomics; 10 Tips to Avoid Ergonomics Disorders

Lighting Ergonomics; What Is The Correct Lighting Position

How to Identify Ergonomic Hazard and Risk Factors

6 Major Types Of Hazards You Should Know

15 Ultimate Safety Goals For Performance Review

A seasoned Health and Safety Consultant with over a decade of hands-on experience in Occupational Health and Safety, UBONG EDET brings unmatched expertise in health and safety management, hazard prevention, emergency response planning, and workplace risk control. With a strong passion for training and coaching, he has empowered professionals and organizations to build safer, more compliant work environments.

Certified in globally recognized programs including NEBOSH, ISO standards, and OSHA regulations, he combines technical know-how with practical strategies to drive health and safety excellence across industries. designing comprehensive HSE management systems or delivering impactful safety training, whether he] is committed to promoting a culture of safety and continuous improvement.