Ergonomics is the science focused on designing workspaces, tools, and tasks to fit the worker’s physical capabilities and limitations, aiming to reduce discomfort and injury risks. In the context of occupational health, ergonomics plays a vital role in minimizing musculoskeletal disorders (MSDs) that arise from poorly designed work environments.

With the increasing prevalence of sedentary desk jobs and repetitive physical tasks, ergonomic injuries have become a major concern for workplaces worldwide. These injuries not only affect workers’ well-being but also significantly impact business productivity due to absenteeism and reduced efficiency.

Understanding ergonomic injuries helps both employers and employees recognize the importance of proper workstation design and safe work practices, thus preventing costly and debilitating health issues. This article explores ergonomic injuries comprehensively—from causes and symptoms to prevention and legal considerations—ensuring a safer and healthier workplace for all.

What is an Ergonomic Injury?

An ergonomic injury refers to physical harm or strain caused by repetitive motions, awkward postures, or prolonged static positions while performing work-related tasks. Technically, these injuries fall under the broader category of musculoskeletal disorders (MSDs), which involve damage or inflammation of muscles, tendons, ligaments, nerves, or joints.

Unlike acute trauma injuries (such as fractures or cuts), ergonomic injuries develop gradually over time due to continuous exposure to poor ergonomic conditions. Examples include repetitive strain injuries (RSI), cumulative trauma disorders (CTD), and overuse syndromes.

Musculoskeletal disorders related to ergonomics often manifest as chronic pain, stiffness, or numbness, especially in the back, neck, shoulders, wrists, and hands. The primary distinction between ergonomic injuries and acute trauma is the gradual onset caused by workplace design flaws or task-related stresses rather than a single sudden event.

Recognizing the technical definition and mechanisms behind ergonomic injuries is crucial for early intervention and effective workplace solutions, reducing long-term disability and enhancing employee quality of life.

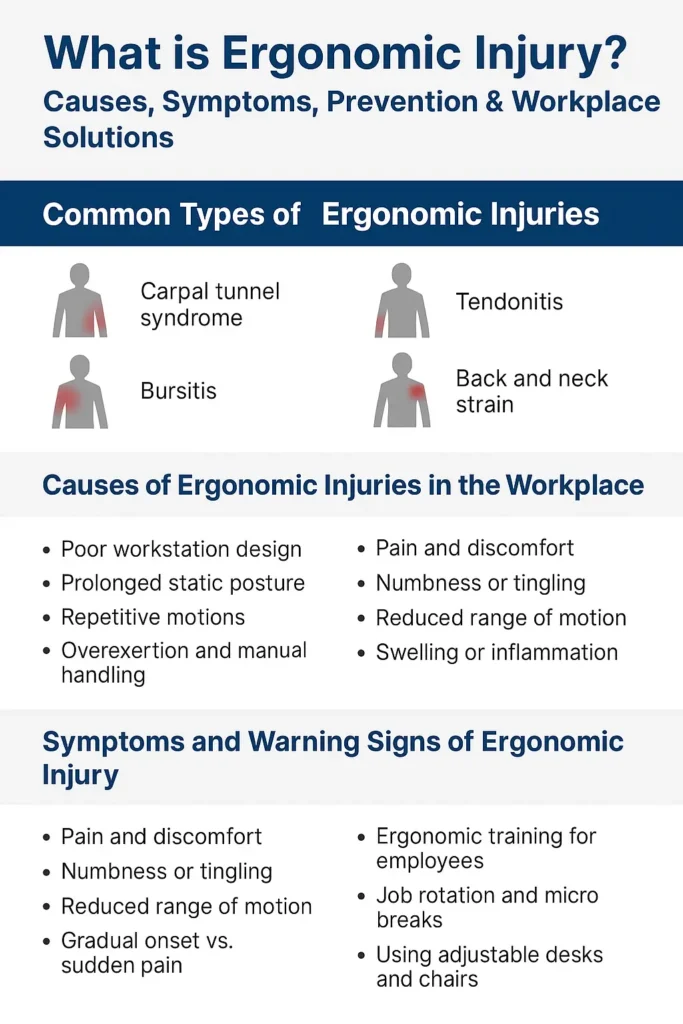

Common Types of Ergonomic Injuries

Several types of ergonomic injuries frequently affect workers across different industries. Understanding these helps identify symptoms early and apply the right prevention strategies.

-

Carpal Tunnel Syndrome: Caused by compression of the median nerve in the wrist, often due to repetitive hand movements or poor wrist positioning. Symptoms include numbness, tingling, and weakness in the hand.

-

Tendonitis: Inflammation of tendons, commonly seen in wrists, elbows, and shoulders due to repetitive motions or overuse.

-

Bursitis: Inflammation of the bursae (fluid-filled sacs cushioning joints), leading to pain and restricted movement, especially in the shoulders, elbows, and hips.

-

Back and Neck Strain: Caused by poor posture, prolonged sitting, or improper lifting techniques, leading to muscle fatigue, spasms, or chronic pain.

-

Tennis Elbow (Lateral Epicondylitis): Painful inflammation of the tendons on the outer elbow due to repetitive wrist and arm motions.

-

Trigger Finger: Tendon inflammation causing fingers to lock or catch when bent.

-

Rotator Cuff Injuries: Damage to shoulder tendons affects mobility and strength.

Visual aids like diagrams or images showing affected areas can be helpful for workplace training or employee education.

Causes of Ergonomic Injuries in the Workplace

Ergonomic injuries stem from various workplace-related factors that impose physical stress on the body. The most common causes include:

-

Poor Workstation Design: Desks, chairs, and equipment that do not fit the worker’s body lead to awkward postures and repetitive strain.

-

Prolonged Static Posture: Sitting or standing in one position for extended periods restricts blood flow and causes muscle fatigue.

-

Repetitive Motions: Continuous, repetitive hand, arm, or body movements without adequate breaks can cause tendon and muscle injuries.

-

Overexertion and Manual Handling: Lifting, pushing, or pulling heavy objects improperly strains muscles and joints.

-

Vibration Exposure: Operating vibrating tools or machinery can lead to hand-arm vibration syndrome (HAVS).

-

Poor Lighting: Inadequate lighting forces workers to strain their eyes and adopt unnatural postures.

-

Inadequate Breaks: Lack of regular micro breaks prevents muscle recovery, increasing injury risk.

These causes are often interrelated, compounding ergonomic stress and injury risks. Proper ergonomic design and workplace policies are essential to mitigate these factors.

Symptoms and Warning Signs of Ergonomic Injury

Recognizing the early symptoms and warning signs of ergonomic injury is crucial for timely intervention and prevention of permanent damage. Common symptoms include:

-

Pain and Discomfort: Persistent or recurring pain in muscles, joints, or tendons, often worsening with activity.

-

Numbness or Tingling: Especially in fingers, hands, or arms, indicating nerve compression or irritation.

-

Reduced Range of Motion: Difficulty moving joints or stiffness after work periods.

-

Swelling or Inflammation: Visible swelling or tenderness around affected areas.

-

Weakness: Loss of grip strength or general muscle weakness.

-

Fatigue: Generalized tiredness or muscle exhaustion related to work tasks.

-

Gradual Onset vs. Sudden Pain: Unlike acute injuries, ergonomic symptoms usually develop slowly but steadily.

Employees should be encouraged to report these signs early to prevent escalation into chronic conditions or disability.

Risk Factors and High-Risk Jobs

Certain jobs and work environments inherently carry higher risks of ergonomic injuries due to the nature of tasks involved. Key risk factors include:

-

Sedentary Office Workers: Prolonged sitting, keyboard and mouse use, and poor posture increase risks of neck, back, and wrist disorders.

-

Healthcare Professionals: Frequent patient lifting, awkward postures, and repetitive tasks contribute to musculoskeletal strain.

-

Construction and Manufacturing Workers: Heavy manual handling, repetitive motions, and vibration exposure are common ergonomic hazards.

-

Drivers and Warehouse Staff: Long periods of sitting or standing combined with manual material handling raise injury risk.

-

Data from OSHA, HSE, and NIOSH: Studies indicate MSDs account for approximately 33% of all workplace injuries and illnesses, highlighting the importance of ergonomic interventions.

Knowing which jobs have higher risks allows targeted prevention efforts to protect vulnerable workers.

How Ergonomic Injuries Affect Worker Health and Business Productivity

Ergonomic injuries have significant consequences beyond individual discomfort. They affect both worker health and overall business performance:

-

Increased Absenteeism: Workers suffering from MSDs may require extended sick leave, disrupting operations.

-

Decreased Efficiency and Morale: Pain and discomfort reduce concentration, speed, and motivation.

-

Financial Impact of Compensation Claims: Employers face higher insurance premiums and costs related to injury claims and medical treatments.

-

Long-Term Disability Risks: Severe cases may result in permanent impairment or the need for job reassignment.

-

Workplace Safety Culture: High injury rates undermine trust and safety commitment among employees.

Addressing ergonomic injuries proactively improves worker well-being and strengthens business resilience.

Prevention Strategies

Prevention is the cornerstone of managing ergonomic risks. Effective strategies include:

-

Ergonomic Training for Employees: Educating staff on correct posture, equipment use, and injury signs.

-

Job Rotation and Micro Breaks: Alternating tasks and encouraging short rest periods to reduce repetitive strain.

-

Using Adjustable Desks and Chairs: Allowing workers to customize their workstations for comfort and support.

-

Correct Lifting Techniques: Training in safe manual handling to avoid overexertion.

-

Incorporating Exercise and Wellness Programs: Promoting physical fitness and flexibility to strengthen musculoskeletal health.

-

Providing Ergonomic Tools: Use of wrist rests, ergonomic keyboards, and anti-fatigue mats.

-

Encouraging Early Reporting: Prompt attention to symptoms to prevent worsening conditions.

-

Workstation Assessments: Regular evaluations to identify and fix ergonomic hazards.

-

Promoting a Safety Culture: Leadership support for ergonomic health initiatives.

These combined measures significantly reduce injury incidence and improve employee satisfaction.

Ergonomic Risk Assessments: What They Are & How to Conduct Them

An ergonomic risk assessment systematically evaluates workplace conditions to identify potential injury hazards. Key steps include:

-

What Is an Ergonomic Risk Assessment? It’s a formal process to assess physical demands, postures, and work environment factors affecting worker safety.

-

Step-by-Step Guide:

-

Identify tasks and workers at risk

-

Observe work processes and postures

-

Gather employee feedback on discomfort

-

Use checklists and measurement tools

-

Analyze findings and prioritize risks

-

Develop and implement corrective actions

-

Monitor improvements over time

-

-

Tools and Checklists: Standardized tools like the Rapid Upper Limb Assessment (RULA), the NIOSH Lifting Equation, and others help quantify ergonomic risk.

-

Role of Occupational Health and Safety Consultants: Experts provide technical knowledge, conduct detailed assessments, and recommend tailored solutions.

Conducting thorough risk assessments is fundamental to designing effective prevention programs.

Workplace Ergonomics Best Practices

Implementing ergonomic best practices creates a safer and more comfortable work environment. Key considerations include:

-

Designing Ergonomic Workstations: Ensuring chairs support the lower back, desks are at an appropriate height, and monitors are eye level.

-

Tools and Technology: Incorporating sit-stand desks, ergonomic keyboards, adjustable monitor arms, and anti-fatigue mats reduces strain.

-

Visual and Environmental Ergonomics: Proper lighting to minimize eye strain, noise control, and maintaining a comfortable temperature.

-

Encourage Employee Feedback and Reporting: Open communication channels help identify new or ongoing ergonomic issues.

-

Use of Assistive Devices: Lifting aids and ergonomic hand tools to reduce physical strain.

-

Training and Refresher Courses: Keeping staff informed of ergonomic best practices.

-

Workspace Organization: Keeping frequently used items within easy reach to prevent awkward postures.

Adopting these practices helps create a dynamic, health-focused workplace culture.

Legal and Regulatory Considerations (e.g., OSHA, HSE)

Employers must comply with legal frameworks designed to protect workers from ergonomic injuries:

-

OSHA Guidelines (USA): While no specific federal ergonomic standard exists, OSHA enforces general duty clauses requiring workplaces to be free of recognized hazards, including ergonomic risks.

-

HSE’s Approach (UK): The Health and Safety Executive provides practical ergonomic guidance and enforces regulations under the Health and Safety at Work Act.

-

ISO 45001: The international occupational health and safety management system standard incorporates ergonomics within risk management practices.

-

Employers’ Legal Duty of Care: Employers must proactively assess ergonomic hazards, provide training, and implement control measures to ensure worker safety.

-

Workers’ Compensation: Injuries caused by ergonomic factors are typically covered under workers’ comp schemes, mandating timely reporting and documentation.

Understanding regulatory requirements ensures workplace compliance and reduces legal liabilities.

Role of Employers and Employees in Preventing Ergonomic Injuries

Preventing ergonomic injuries requires collaboration between employers and employees:

-

Shared Responsibility: Employers provide safe work environments and resources; employees follow ergonomic practices and report hazards.

-

Importance of Reporting Early Symptoms: Early disclosure helps prevent injury progression.

-

Developing an Ergonomics Policy: Formal policies guide workplace ergonomic practices and responsibilities.

-

Creating a Safety-First Culture: Leadership commitment to health and safety fosters employee engagement.

-

Providing Continuous Training: Ongoing education reinforces correct behaviors and updates on new tools or practices.

-

Regular Monitoring and Feedback: Encouraging open dialogue helps adapt solutions to evolving workplace needs.

A culture of shared accountability enhances prevention effectiveness.

Case Study Example (Real-Life Scenario)

Company Profile: A mid-sized manufacturing firm experienced high rates of back and wrist injuries, leading to lost workdays and increased compensation costs.

Steps Taken:

-

Conducted comprehensive ergonomic risk assessments with an external consultant.

-

Redesigned workstations with adjustable chairs and tables.

-

Implemented employee training focused on safe lifting and posture.

-

Introduced job rotation and regular micro breaks.

Outcome: Within 12 months, injury claims dropped by 60%, absenteeism decreased, and overall employee morale improved.

Lessons Learned: Early intervention, expert consultation, and active employee involvement are critical for sustainable ergonomic improvements.

Conclusion: Key Takeaways

Ergonomic injuries are preventable workplace conditions caused by poor design and repetitive strain. They impact worker health, productivity, and business costs. By understanding causes, symptoms, and risk factors, organizations can implement targeted prevention strategies, including ergonomic training, workstation redesign, and risk assessments.

Employers and employees must share responsibility in creating a culture of safety and proactive injury prevention. Legal compliance and continuous monitoring ensure lasting workplace improvements. Regular ergonomic evaluations and early symptom reporting are essential for maintaining healthy, productive workers.

Frequently Asked Questions

Q1: Are ergonomic injuries covered by workers’ compensation?

Yes, most ergonomic injuries that arise from work conditions are covered under workers’ compensation insurance, provided they are properly reported and documented.

Q2: How long does it take to recover from carpal tunnel syndrome?

Recovery varies by severity and treatment but typically ranges from weeks to several months, with some cases requiring surgery for full recovery.

Q3: Can ergonomic injuries be reversed?

Early-stage ergonomic injuries can often be reversed with rest, treatment, and workplace modifications. Chronic injuries may require long-term management.

Q4: What are the best ergonomic tools for office workers?

Adjustable chairs, sit-stand desks, ergonomic keyboards and mice, wrist rests, and monitor stands are among the best tools.

Q5: Who is responsible for ergonomic assessments in the workplace?

Employers hold primary responsibility but may engage occupational health and safety consultants. Employees should also participate by reporting discomfort and hazards.

Q6: How often should ergonomic risk assessments be conducted?

Regular assessments should occur at least annually or whenever significant workplace changes happen.

Q7: What exercises help prevent ergonomic injuries?

Stretching, strengthening exercises for the back, neck, shoulders, and wrists, and regular movement breaks help maintain musculoskeletal health.

Read Also: 11 Valid Ergonomics Principles for Preventing Musculoskeletal Disorders in the Workplace

Related Post

What is Lighting Ergonomics: How it Affects You

What is Injury: Exploring the Causes and Prevention Options

How to Identify Ergonomic Hazard and Risk Factors

Ergonomic Evaluation of Workstation; What to Look Out For

A seasoned Health and Safety Consultant with over a decade of hands-on experience in Occupational Health and Safety, UBONG EDET brings unmatched expertise in health and safety management, hazard prevention, emergency response planning, and workplace risk control. With a strong passion for training and coaching, he has empowered professionals and organizations to build safer, more compliant work environments.

Certified in globally recognized programs including NEBOSH, ISO standards, and OSHA regulations, he combines technical know-how with practical strategies to drive health and safety excellence across industries. designing comprehensive HSE management systems or delivering impactful safety training, whether he] is committed to promoting a culture of safety and continuous improvement.