Understanding and complying with General HSE OSHA Standard Limits is crucial for maintaining a safe and healthy work environment across various industries, including construction, manufacturing, oil and gas, chemical processing, and other labor-intensive sectors. The Occupational Safety and Health Administration (OSHA) establishes specific regulatory limits to reduce the risk of occupational injuries, illnesses, and fatalities by controlling exposure to various physical, chemical, and environmental hazards. These standards act as a benchmark for employers when designing safety controls, conducting risk assessments, and developing emergency response systems.

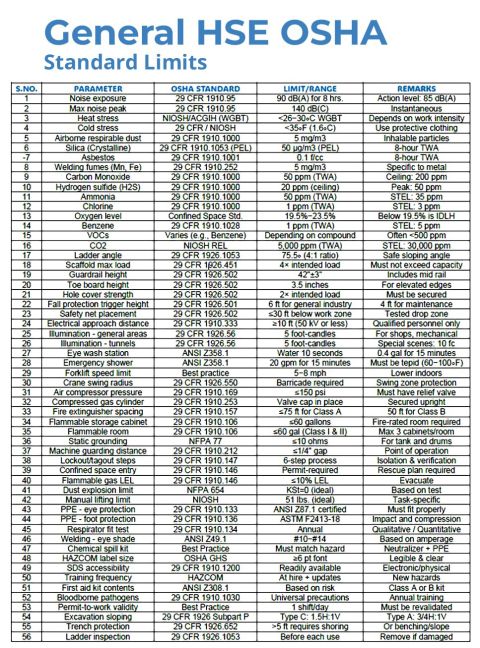

The table provided outlines more than 50 OSHA-regulated parameters that cover a wide range of workplace hazards, including noise, chemical exposure, temperature extremes, respiratory threats, confined spaces, fire safety, PPE usage, machinery operation, and fall protection. Below is a detailed SEO-optimized summary of the most important OSHA standard limits and what employers and safety professionals must know to stay compliant.

OSHA Standard Limits

1. Noise Exposure and Hearing Protection

OSHA mandates strict limits for noise exposure to prevent hearing loss. According to 29 CFR 1910.95, workers must not be exposed to more than 90 dBA for 8 hours, and an action level is triggered at 85 dBA, requiring hearing conservation programs. Peak noise levels are regulated under 29 CFR 1910.95 and must not exceed 140 dBC, ensuring workers are protected from impulse noise such as explosions or sudden mechanical impacts. These standards help minimize long-term hearing damage, a common occupational hazard.

2. Temperature and Heat Stress Management

Heat stress is a serious risk, especially in outdoor work or high-temperature indoor environments. OSHA relies on NIOSH/ACGIH (WBGT) guidelines to determine safe exposure levels, highlighting the importance of hydration, work-rest cycles, and environmental monitoring. Cold stress parameters are guided by 29 CFR NIOSH, helping employers plan for extreme cold conditions, preventing frostbite, hypothermia, and reduced motor performance.

3. Airborne Contaminants and Respiratory Safety

OSHA sets stringent limits for airborne hazards like dust, silica, and asbestos. For example:

-

Airborne respirable dust: 29 CFR 1910.1000

-

Silica (crystalline): 29 CFR 1910.1053 – 50 µg/m³ PEL, 8-hr TWA

-

Asbestos: 29 CFR 1910.1001 – regulated for lung protection.

These standards require engineering controls such as ventilation, dust suppression, and mandatory respiratory protection. The goal is to prevent chronic respiratory illnesses, occupational cancer, and long-term pulmonary impairment.

Read Also: Which Government Agency Is Charged With Workplace Safety in Canada?

4. Chemical Exposure and Hazardous Substances

Many of the OSHA limits listed in the table relate to toxic gases and chemicals, such as:

-

Hydrogen sulfide (H₂S) – 29 CFR 1910.1000 (Ceiling limit: 20 ppm)

-

Carbon monoxide – 29 CFR 1910.1000 (50 ppm TWA)

-

Ammonia – 50 ppm TWA

-

Chlorine – 1 ppm TWA

-

Benzene – regulated under multiple OSHA subparts with limits like 1 ppm TWA

These limits ensure workers are not exposed to harmful concentrations that can cause poisoning, respiratory distress, or chemical burns. Industries handling petroleum, wastewater, chemicals, or manufacturing must strictly follow these thresholds.

5. Confined Space Hazards and Oxygen Levels

OSHA’s Confined Space Standard requires maintaining oxygen levels between 19.5% and 23.5%. Oxygen deficiency or enrichment can cause severe physiological consequences and increase explosion risks. Hazardous gases like H₂S, CO, and VOCs must be monitored before and during entry. This ensures proper implementation of atmospheric testing, ventilation, and permit entry systems.

6. Evacuation, CO₂ Exposure, and Emergency Preparedness

OSHA also regulates evacuation requirements and CO₂ exposure, with a 5,000 ppm TWA limit under ANSI standards. Employers must develop evacuation procedures that ensure rapid and safe worker movement during emergencies. Proper signage, lighting, and communication systems support effective incident response and compliance.

7. Working at Heights, Scaffolding, and Fall Protection

Fall hazards remain one of the most common causes of workplace fatalities. OSHA mandates:

-

Scaffold rail height: 38–45 inches

-

Guardrail height: 42 ± 3 inches

-

Toe board height: 4 inches

-

Fall protection height: 6 ft for construction, 4 ft for general industry

-

Ladder slope ratio: 4:1

Additionally, hole covers must support at least twice the expected load, ensuring safety during construction and maintenance activities. Personal fall arrest systems (PFAS) must meet ANSI Z359 requirements.

Read Also: Which Government Agency Is Responsible for Workplace Safety in the UK?

8. Illumination, Stairs, and Egress Systems

OSHA emphasizes proper visibility and safe movement within workplaces. Standards include:

-

Work area illumination: 20 lumens (office), 10 lumens (general), 5 lumens (low-use areas)

-

Stair standards: 29 CFR 1910.25

-

Exit routes: Must be illuminated with at least 1 foot-candle

These parameters help prevent slips, trips, and falls and improve evacuation readiness.

9. Flammable Materials and Fire Safety Compliance

Fire hazards are strictly regulated through:

-

Flashpoint handling: 100°F for flammable substances

-

Storage limitations as per NFPA 54

-

Combustible distance: 36 inches from ignition sources

Employers must manage flammable materials using fire-rated cabinets, proper ventilation, and ignition control. This reduces explosion and fire risks significantly.

10. Electrical Safety, Lockout/Tagout, and Arc Flash Protection

OSHA electrical standards cover:

-

Disconnecting means: OSHA 1910.147 (LOTO)

-

Grounding: OSHA 1910.304

-

Arc flash boundaries: NFPA 70E – calculated based on voltage and fault current

-

Breaker panel clearance: 36 inches

Proper implementation prevents electric shock, arc flash injuries, and electrocution incidents.

11. Personal Protective Equipment (PPE) and Respiratory Protection

OSHA outlines detailed PPE standards, including:

-

Respirator fit testing: 29 CFR 1910.134

-

Hard hats: ANSI Z89.1

-

Safety shoes: ANSI Z41

-

Eye/face protection: ANSI Z87.1

Each category ensures that workers are adequately protected based on hazard assessment.

12. Chemical Handling, Spill Control, and Hazard Communication

Standards such as 29 CFR 1910.120 and 1910.178 require proper chemical storage, spill containment, and hazard labeling. Gas cylinder storage must be upright, secured, and capped when not in use. Chemical-resistant gloves, spill kits, and SDS availability are mandatory for compliance.

13. Permit-Required Confined Spaces and Safe Work Procedures

Under 29 CFR 1910.146, certain spaces require permits before entry. Requirements include:

-

Atmospheric testing

-

Ventilation

-

Attendant monitoring

-

Rescue plan

These procedures prevent toxic exposure, entrapment, and oxygen deficiency.

Conclusion: Importance of Following OSHA Standard Limits

The OSHA HSE limits summarized above serve as critical benchmarks for employers dedicated to maintaining safe and compliant work environments. These limits reduce exposure to harmful chemicals, toxic gases, excessive noise, temperature extremes, fall hazards, electrical dangers, and more. Organizations that follow OSHA guidelines experience fewer incidents, improved worker health, reduced liability, and higher productivity.

Safety professionals should use these OSHA standard limits as part of continuous workplace monitoring, employee training programs, hazard assessments, and preventive maintenance activities. With proper implementation, companies can protect their workforce, achieve regulatory compliance, and foster a strong culture of workplace safety.

A seasoned Health and Safety Consultant with over a decade of hands-on experience in Occupational Health and Safety, UBONG EDET brings unmatched expertise in health and safety management, hazard prevention, emergency response planning, and workplace risk control. With a strong passion for training and coaching, he has empowered professionals and organizations to build safer, more compliant work environments.

Certified in globally recognized programs including NEBOSH, ISO standards, and OSHA regulations, he combines technical know-how with practical strategies to drive health and safety excellence across industries. designing comprehensive HSE management systems or delivering impactful safety training, whether he] is committed to promoting a culture of safety and continuous improvement.